- Market globalization and fast-paced technological change have raised customer expectations, and companies can succeed or fail depending on their ability to deliver the right goods at the right price, at the right time, via the right distribution channels.If getting it wrong can be costly, it right takes time. It means constantly evaluating every part of the production process to see where it can be made more efficient without a perceived drop in quality or sales. Henry Ford was the first industrialist to recognize the value of offering customers “more for less,” and made it his business to make improvements to his cars every year, while simultaneously dropping their price. Today, many use a “low cost, good quality” strategy to attract customers, especially during times of recession.

- One of the most effective ways of lowering costs while maintaining value is to reduce waste. Outside of a business context, ’lean’ means ’thin in a healthy way / ’no fat’. In a business context, it refers to an approach which tries to meet demand instantenously with perfect quality and no waste. Lean production developed from the ideas of Joseph Juran, a management consultant who developed innovative ways of improving quality and efficiency at the same time. In the 1950s, the Union of Japanese Scientists and Engineers invited him to lecture to hundreds of top-level executives, who quickly put his ideas to practical use. Toyota was among the many businesses who implemented his methods. The company’s approach ultimately grew into the “just-in-time” production system that is widely used today.

- Lean manufacturing:

- ’Kanban’: using a ’pull’ system where production responds quickly to real, observed demand. This contrasts with a ’push’ system where production is based on forecasts of demand (which may not be accurate).

- Flexible manufacturing: designing machines to do multiple tasks; reprogramming machine tools while they are running

- Mass customization: tailoring products to meet the needs of a large number of individual customers.

- The techniques used for lean operations are often called ’just-in-time’ (JIT) techniques. These include:

- Making every effort to eliminate waste

- Developing working practices which support ’continuous improvement’ (often called by its Japanese name ’kaizen’).

- Involving all staff in quality initiatives.

- Improving the flow of work-in-progress around the plant by rearranging layout and using machines that are small, simple, robust and flexible.

- Reducing set-up and change-over times.

- Incorporating manufacturing considerations into the design process (reducing production costs by reducing design complexity).

Why use JIT techniques? Because materials, work-in-progress and finished goods that are not being used represent a waste ot time, space and money.

- The Toyota Production System (TPS)

a., History: TPS is the basis of modern manufacturing. It was developed at Toyota at the end of the 70s and during the 80s, but it is now used right across the industry. In the 1950s, Toyota was a relatively inefficient producer of cars. Like many other Japanese companies, Toyota was struggling to overcome the shortages created by an economy that had been devastated by war. Looking for ideas, Toyota sent a young engineer, Eiji Toyoda, to the US to visit Ford’s Rouge plant in Detroit, MI. Toyoda spent three months studying the mass-production technique pioneered by Ford at the Rouge. On his return, Eiji reported that he was impressed by the scale of production that Ford achieved— the Rouge was so big that it required its own railroad, hospital, and several fire stations. However, he also believed that the factory was riddled with muda—the Japanese term for wasted effort, materials, and time. Toyoda and his colleagues set about developing a new production system that sought to replicate the output and economies of scale achieved by Ford, but in a less wasteful manner.

b., Muda: TPS focuses on two things: adding value and eliminating waste. Value is defined as any item or feature for which a customer is willing to pay. Anything else is waste and has to be removed. TPS identifies seven categories of waste (muda):

a., overproduction: producing too much, or too soon, or too quickly. Overproduction is minimized by using a ’pull’ system; this means that work isn’t performed unless the part is required downstream

b., materials handling: inside and outside the plant

c., movement: performing tasks manually that could be automated.

d., waiting: idle time between work stations along the production line

e., over processing: doing more than the customer required or is willing to pay for (value analysis)

f., inventory: exceeding one-piece flow. One-piece flow (= continuous flow) is when items are processed one at a time and then moved directly to the next process.

g., defects: rework, repair, or waste in its simplest form. Defects are rigourously analyzed to make sure that they don’t happen again (ie. ’error-proofing’ the system).

Case study: Volkswagen: In 2012, Volkswagen announced its intention to become the world’s most environmentally friendly car manufacturer by 2018. To achieve this goal, the German company set out to reduce waste during the production process. When cars are produced, sheet steel is cut out to form parts of the chassis. If this process if not managed effectively, expensive steel can end up being wasted as off-cuts. The management at Volkswagen achieved a 15 percent reduction in the amount of steel used to produce each car by investing in new cutting machinery and by changing the dimensions of the steel sheets to reduce off-cut waste. In the paint shop, the amount of paint used to produce a vehicle was halved by installing state-of-the-art painting robots. These savings meant that Volkswagen could reduce their prices. For example, the price of a Golf Cabriolet was reduced by approximately $10,600 in June 2013. Reductions like this contributed to a 6 percent rise in global sales by May 2013.

c., Gemba: Gemba is a Japanese word meaning “the real place,” in a business context gemba refers to the place where value-added is created. Kaizen is founded on the conviction that the production-line worker is the gemba expert who knows where the problems are. Therefore, most of the ideas for kaizen change should come from the factory-floor workers, rather than from management. This is because difficulties and abnormalities can only be analyzed and fixed at the gemba, not from the desk. Kaizen philosophy recognizes that a company’s greatest resource is its employees. Kaizen is more likely to be effective if workers are asked to work as teams, rather than as isolated individuals. The process of coming up with good ideas and solutions is often the product of the synergy created by people that have different skill sets, qualifications, or ways of seeing the world. Working as a team on kaizen projects is known as being part of a “quality circle.” The quality circle consists of a group of people who usually work together—for example, on the same part of an assembly line—as well as individuals from other parts of the business who can bring different perspectives. For example, an engineer could provide advice on technical matters, while sales-team members can give the group an insight into the customer’s point of view.

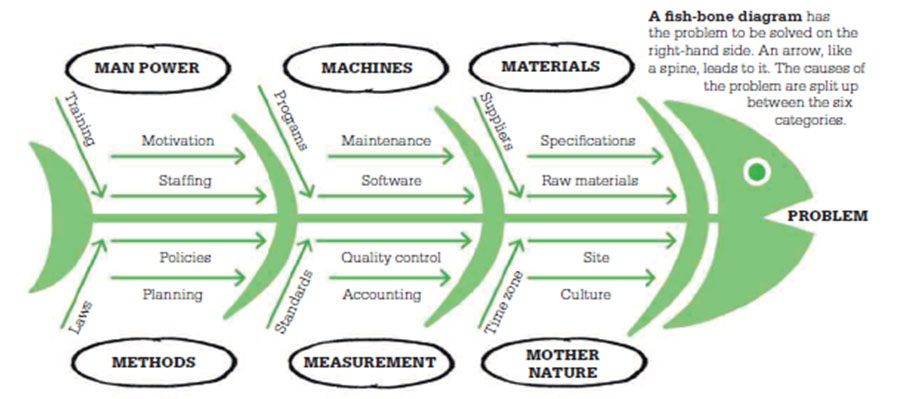

d., Asa-ichi and fish-bone diagram: fish-boneIn 1964, Toyota established quality circles at its factory in Toyota City, Japan. The quality circles still meet regularly, at least once a week, to discuss any of the problems they have noticed on their section of the production line. Each morning employees are expected to attend an asa-ichi (morning) meeting with a positive attitude, before the regular working day begins. At this meeting they discuss quality problems and possible solutions to those problems. One of the main tools used by Toyota’s quality circles to generate kaizen ideas is the “fish-bone” diagram. This is a graphic device that uses the outline of a fish skeleton to plot all the various aspects of a problem and then explore a number of solutions. Quality circle members are asked to identify possible causes for the problem, and each suggestion is classified into one of six categories: Manpower, Methods, Machines, Materials, Measurement (inspection), and Mother Nature (environmental factors). Solutions to each of the possible causes of the problem are evaluated by the circle using the “five Ws,” which are the five questions: Why, When, Where, Who, and What.

e., Practical implementation of kaizen (continuous improvement) / The Five Ss

- Principle: a place for everything, and everything in its place

- Key ideas: discipline, simplicity, pride, standardization and repeatability

- S1: Sort: Review everything in the work area, separating what is needed from what is not. Remove anything unnecessary

- S2: Set In Order: Arrange everything in a neat, tidy and easy-to-use manner

- S3: Shine: Once the work area has been sorted and set in order, clean it up so that everything shines! Clean the area itself, as well as equipment and tools

- S4: Standardize: Create clear, simple and visual standards for S1-S3

- a., shadows on work surfaces and inside storage boxes show which tools should be where

- b., a re-order card (called a ’kanban’) is attached to an item and placed somewhere after the item is used. This gives a visual signal when a new item is needed.

- S5: Sustain: Continue to operate and improve S1-S4

- Stock control plays a large part in the “just-in-time” system, and is vital to a balanced cash flow. Too much stock in the warehouse represents money that is doing nothing; if there is not enough stock to meet demand, customers may search out alternative suppliers. Most firms hold buffer stock – stock that exceeds the amount needed to meet current deamand.

The most important idea of lean operations is that of minimizing inventory kept on the premises – both stock and work-in-progress (WIP). So parts, components, raw materials and other supplies are delievered to the factory just as they are needed. And once delivered, the throughput (= rate at which work goes through the system) is fast.

- Note that with lean operations the capacity utilization (= ratio of actual output to potential output) is often low. This is a difference with traditional approaches. Note also that the need to carry inventory doesn’t disappear – it just shift to suppliers.

- Cost reduction is the holy grail of production managers, and one way to achieve this is to simplify production methods. This involves removing unnecessary and costly steps, or innovating so that stages become faster or less wasteful.

Case study: Steel industry: During the Industrial Revolution, huge quantities of steel were needed to build bridges, ships, and railroads. Steel was in short supply because it was expensive to produce. In Britain, steel had been made in high-temperature, coke-fired furnaces since the 1740s. Small quantities of iron were loaded into small clay crucibles (containers that withstood heat) and placed inside the furnace. After three hours, impurities were scraped from the crucibles, leaving the steel behind. In the 1850s the production method was simplified by the British engineer Henry Bessemer. His so-called Bessemer process did not require crucibles. Instead, the impurities generated from heating iron to create steel were removed from the metal by blowing air through the iron during the production process. Bessemer’s simpler production method was more fuel efficient. As a result, the cost of making steel fell from as much as $97 (Ł60) per ton to $11 (Ł7) per ton. In some cases, simplifying a process can mean using different materials. In 1946 in the US, James. Watson Hendry invented plasticinjection-molding technology, which was used to produce one-piece chairs and tables mure cheaply than wood.

Case study: Ford: In the early 1900s, Henry Ford revolutionized manufacturing by standardizing the method used to make cars. Before Ford’s assembly line, cars were made by teams of highly skilled craftsmen who produced custom-made cars using little more than hand tools. The components used by early manufacturers were usually nonstandardized. This meant that workers would spend time adjusting components so that they could be assembled.

Ford removed this stage by designing the world’s first standardized car. Mass production of the Model T, made from a standard set of components, began in 1910 in Highland Park, Michigan.

Ford’s second great innovation was the conveyor belt. In the past, skilled workers had to move around the factory locating raw materials, components, and tools. In some factories workers were hired to push partially assembled cars from one workstation to another. Ford believed these were unnecessary steps that could easily be removed. People were taken out of the production process and were replaced by specialized machinery, including a conveyor belt that took the work to the worker. Each employee was asked to perform a single task, using the same tool, over and over again. As a result, there was no time wasted searching for, picking up, and putting down an array of tools.

Finally, Ford removed variety from the production process. Each Model T produced was identical; Ford believed in simplicity of product, even down to the paint color, which speeded up production. Time spent resetting and cleaning machines between batches was avoided. A standard product made it possible to institute continuous-flow production, and the amount of time taken to produce a car dropped from over 12 hours to just over one and a half hours.Ford’s decision to simplify production by removing skilled labor and time from the process enabled him to produce his cars at a lower cost, which he then used to reduce the price, and that created a mass market for the Model T.

Case study: Dell: In more recent times, computer manufacturer Dell achieved stratospheric rates of growth in the 1990s by streamlining its supply chain. Michael Dell, the founder of the company, based his business model on gaining a cost advantage over his rivals. He did this in two ways.

First, Dell specialized in selling custom-made computers; customers could design their own machine, which Dell assembled in response to a specific customer’s order. Dell held virtually zero stock and production was pulled through by the buyer. The main advantage of this just-in-time method was that Dell no longer had to pay the costs associated with storing stock. When a product was finished, it was sent straight to the customer.

Dell’s second cost advantage was that, unlike other PC suppliers, it did not sell its products to specialized retailers; instead, it sold directly to the consumer via the Internet. This meant that the company no longer had to lose some of its profit margin to third parties. When Dell sold a computer for $400, it received $400. Eliminating retailers did not have an adverse effect on Dell’s market share. In fact, the reverse was true. Most computer buyers preferred the flexibility of being able to build exactly the sort of computer that they wanted, and also appreciated the convenience of home delivery. Dell’s simplified business model delivered lower costs, enabling the company to gain market share by undercutting the prices charged by rival computer suppliers. The success of Dell’s model of selling directly to consumers was adopted by companies in other industries. In 1996, Amazon, now the world’s biggest online store, began selling books online without the need—or costs—of running a bookstore.

However, since 2000 Dell has lost ground to a revitalized competition. Some companies copied Dell’s idea to sell computers directly to customers, while others, such as Hewlett-Packard, were able to nullify Dell’s price advantage by making their production process more efficient. The resurgence of Apple has also dented Dell’s market share. Apple produces a range of products to suit different budgets, and also allows its customers to make some adjustments to the computer’s specifications.

- Innovation can come from any part of the business. The Japanese idea of kaizen—meaning continuous improvement—is an ancient philosophy, but it was first used in an industrial setting by Toyota in the 1950s. Founder Elji Toyoda expected all employees—from the factory floor to senior executives— to constantly come up with ideas for improving products or production. This idea took hold around the world. Companies recognized value in setting up teams to increase creativity. However, large companies often limit innovation—or at least the testing of its validity—to an R&D (research and development) department. They can focus on the changing needs of markets and respond appropriately, making sure they benefit from the premium price of innovative products, and build a brand loyalty. More recently, companies have also begun to value the creativity of their customers. Using an approach known as “open innovation,” new ideas are welcomed from all sources, and customer feedback is valued in the product-development process. The opportunity for customers to post product ratings and reviews online allows ready access to customer feedback. Some even use online crowdsourcing to refine the design of products.

- Computer systems can collect and yield vast amounts of accurate data, which can translate into valuable information about employees, production lines, and markets. Data collected about customers is often referred to simply as “big data.” Customer buying preferences and habits can now be tracked with incredible accuracy—from their movements around a website, to where and how they like to buy products and services, both online and in stores. This gives an accurate picture of their overall market, while also targeting individual customers, offering them products in tune with their preferences.

- Companies aim to satisfy customers to get repeat business and good “word-of-mouth,” which can hugely boost sales. Those that operate in the fast-moving-consumer-goods (FMCG) market, selling such things as chocolate, beer, and cereals, rely on quality for creating customer loyalty. In the service industries, following this “added-value” approach can be problematic. If competing companies raise the quality of their product or service to a level that would be unprofitable to match, this would signal the need for new strategic thinking. However, high-quality goods can last for a long time without needing replacement, and this was problem addressed by industrial designer Brooke Stevens. He suggested that companies could increase sales by creating in consumers the “desire to own something a little better, a little sooner than necessary.” This seems especially true today, when new models of products such as smartphones are produced regularly—well before their predecessors are defunct. For a smooth, fast route to a high-quality product, companies need to make best use of time and resources. This has led to the development of a way of working known as “timebased management,” which involves utilizing time in the same way as raw materials. It is often used with critical-path analysis, which identifies all the stages of a project and puts them into a logical order, saving companies time and money.

Video 1: Just In Time

![]() Exercise 1: JIT QUIZ

Exercise 1: JIT QUIZ

Video 2: Taiichi Ohno on the Toyota Production System

How would you describe Mr Ohno and his methods?

![]() Exercise 2: Logistics and Warehousing

Exercise 2: Logistics and Warehousing